High-Precision Metal Stamping Services

Phoenix Metal is a trusted provider of custom metal stamping services for the automotive, heavy-duty trucking, and industrial sectors, among others. Our high-precision metal stamping solutions are engineered to meet the performance and reliability standards of today’s most demanding applications. Whether developing components for vehicles, HVAC units, or military-grade equipment, Phoenix Metal’s commitment to quality and innovation ensures optimal results.

Learn how our vast experience and advanced capabilities allow us to serve as a strategic partner in your supply chain from early prototyping to high-volume production.

Automotive & Heavy-Duty Trucking Metal Stamping

In automotive and heavy-duty trucking, consistency and structural integrity are critical. Phoenix Metal produces components such as body panels, mounting brackets, and powertrain components that meet tight tolerances and rigorous quality benchmarks. Our precision industrial stamping processes ensure repeatability across thousands of parts, providing the performance clients need to stay competitive.

Industrial & Custom Metal Stamping Solutions

Our expertise goes far beyond vehicle applications. Phoenix Metal supports a wide array of industrial sectors, including HVAC, medical devices, lighting, telecommunications, and mass transit. We also provide custom metal stamping solutions for specialized industries. From simple stamped brackets to highly complex enclosures and assemblies, we ensure our components meet exact performance, dimensional, and material specifications.

Advanced Metal Stamping Capabilities & Materials

High-Tonnage Stamping Presses for Large-Volume Runs

Phoenix Metal’s facility features stamping presses ranging from 15 to 200 tons, giving us the ability to handle a variety of material thicknesses and part geometries. From thin-gauge precision parts to heavy-duty components, our equipment enables rapid, repeatable output, making our services ideal for high-volume production. This press range aligns with leading industry practices where companies employ high-tonnage capabilities to efficiently produce precision-stamped components across various applications.

Versatile Material Selection for Metal Stamping

Material choice plays a critical role in manufacturability and end-use performance. That’s why we work with a wide variety of metals, including cold-rolled steel, stainless steel, aluminum, copper, and phosphor bronze. Our equipment accommodates stock thicknesses from 0.007 inches to 0.250 inches to give our clients maximum flexibility in design and application. This diverse material portfolio supports a range of performance characteristics, such as corrosion resistance, conductivity, and weight considerations, which are all customizable to meet each application’s requirements.

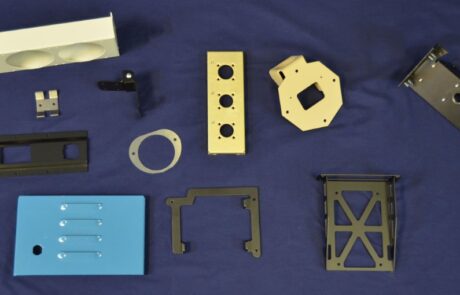

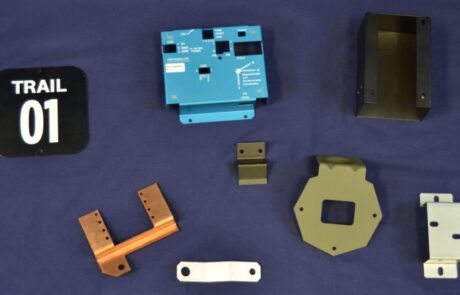

Metal Stamped Products – Engineered for Performance

Precision-Stamped Components for Automotive & Industrial Use

Our product catalog includes an array of precision metal-stamped parts, including:

- Structural brackets

- Connector housings

- Chassis components

- Terminal enclosures

We serve customers across industries with parts that require tight tolerances, robust material strength, and consistent repeatability. We develop each product to meet the specific performance expectations of clients across sectors while ensuring the quality and durability standards required for their specific application.

Surface Finishing & Secondary Processes

To meet unique finishing and secondary process requirements, Phoenix Metal offers in-house powder coating and additional finishing treatments such as anodizing, black oxide, zinc plating, and e-coating. These can enhance durability, improve appearance, and meet specific environmental and safety regulations to ensure each component is ready for immediate and long-term performance.

Quality & Compliance in Precision Metal Stamping

ISO 9001:2015-Certified Metal Stamping Processes

At Phoenix Metal, quality is embedded into every step of our process. Our ISO 9001:2015 certification reflects our commitment to consistent quality, process control, and customer satisfaction. By adhering to international standards, we ensure every project meets or exceeds client expectations, aligning our operations with the best practices recognized across the larger metal stamping industry.

Scalable Production for High-Volume Metal Stamping

Phoenix Metal uses advanced systems, high-precision tooling, and a layout designed for lean manufacturing to meet high-volume metal stamping needs. Like other top-tier manufacturers, we are equipped to handle a high number of stamped parts annually while maintaining tight tolerances and consistent quality, making us a reliable partner for large production runs in rapidly growing or time-sensitive industries.

Precision Metal Stamping Services by Phoenix Metal

At Phoenix Metal, we combine technical expertise, advanced equipment, and a client-focused approach to deliver best-in-class custom metal stamping services. From small brackets to large structural components, our solutions are built around your performance, budget, and timeline requirements.

Whether you’re developing a new product line or scaling production of an existing component, we’re ready to help you meet your goals with precision, speed, and confidence. Request a custom quote to get started.

Do you have any questions or comments?