Established in 1983, Phoenix Metal Fabricating Inc. offers an array of design and fabrication services to support clients in industries ranging from automotive to medical. We specialize in metal fabrication and stamping, welding and assembly, powder coating, and more. With our laser cutting services, our skilled team is able to create custom precision products per our clients’ unique specifications.

What Is Laser Cutting?

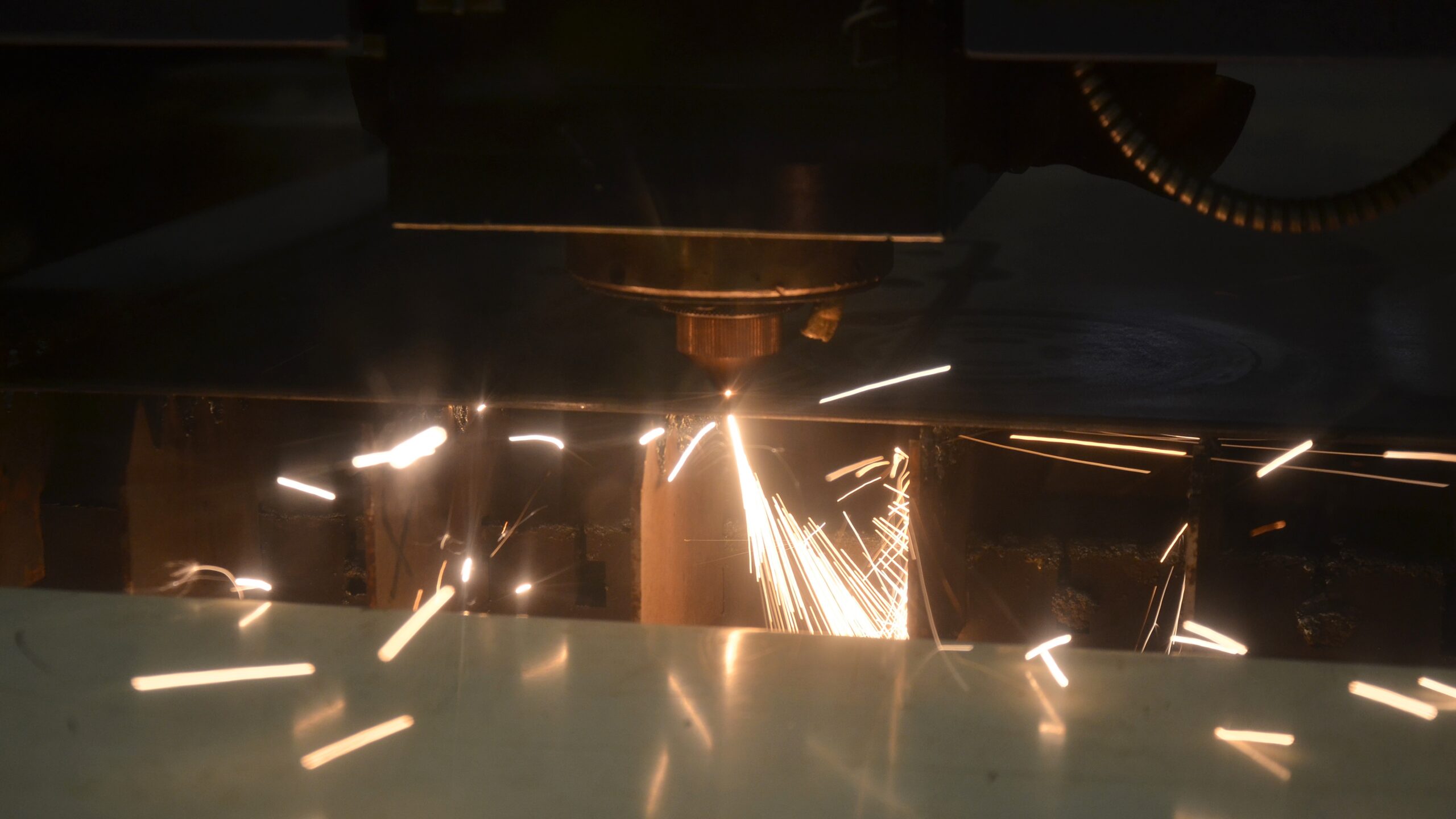

The laser cutting process utilizes a powerful, highly focused beam of light to generate clean cuts in various objects or raw materials. In addition to cutting, lasers can perform such processes as laser etching, engraving, and marking due to the exceptional level of control and accuracy the technology offers.

Laser Cutting Capabilities at Phoenix Metal

To deliver the best results for our clients, our three facilities are equipped with state-of-the-art machinery and technology. For our laser cutting services, we utilize the following powerful machines for their speed and efficiency:

- 2018 Mitsubishi 3015 EXF featuring a 5×10 4500 W fiber laser cutting system with a zoom head

- 2025 AMADA ENSIS 3015 AJe Series featuring a 5×10 12 kW fiber cutting system with automated loading (Coming in 2026!)

Materials

With this equipment, we’re capable of working with a range of material options, including:

- Mild steel: 0.020″ to 0.500″

- Stainless steel: 0.020″ to 0.375″

- Aluminum: 0.020″ to 0.250″

Benefits of Laser Cutting

Laser cutting is highly advantageous for custom fabrication thanks to its broad range of benefits. These include:

- High precision for narrower cuts. The cutting process is extremely precise, partly because, unlike CNC routers and other alternative cutting devices, laser cutter heads don’t carry load. Also, laser beams are exceptionally focused, allowing them to make cuts as narrow as 0.1 mm in certain materials.

- Automation and cutting speed. Laser cutting is an automated process, enabling equipment to cut two-dimensional shapes from your chosen material both accurately and rapidly — particularly if that material is soft. Certain laser cutters even have the ability to handle raw material placement on cutting beds or unload components, further minimizing worker involvement and reducing production time.

- Material and process versatility. Laser cutting machines are effective on nearly any material type. Their capacity for material thickness, however, is dependent upon the material, the power of the laser, and the technology the equipment uses. This equipment is also capable of performing more than one function, adding to its flexibility.

- Minimal finishing requirements. The edges of laser-cut components don’t typically require the finishing work or secondary treatments that are often necessary for parts made with other fabrication techniques. That said, metal part edges may still need deburring to remove slag.

- Tooling cost savings. In addition to saving on post-processing treatments, you’ll also save on tooling compared to processes like CNC machining because laser cutting doesn’t require an assortment of tools. Also, the material doesn’t come into direct contact with the laser cutter head, so there’s no friction that could otherwise result in tool wear.

- No need for workholding devices. The laser cutting process doesn’t necessitate workholding components like clamps to secure materials in place. Once your material is on the cutting bed, it will remain stationary until the process is finished.

Common Applications of Laser Cutting

An incredibly versatile process that’s well suited to diverse industries and material types, laser cutting is effective for such applications as:

- Sheet metal cutting. Laser cutting equipment can easily cut plates and sheets of durable metals of various types, hardnesses, and thicknesses.

- Tube cutting. Some laser machinery features a rotational axis, which supports its ability to make complex cuts in lengths of hollow tubing.

- Laser welding. Laser technology can weld materials together, allowing technicians to fuse metal components without the need for electric arc welders.

- Engraving. It’s also possible for laser cutters to engrave materials, marking them with anything from standard text or serial numbers to designs.

Laser Cutting Services From Phoenix Metal

Laser cutting has transformed the metal fabrication and manufacturing sector. This versatile process enables manufacturers to quickly and accurately achieve the desired cuts or markings in a variety of materials. With little material waste and finishing requirements, precision laser cutting is a value-add service offering from any job shop.

At Phoenix Metal, our laser cutting services are just one part of our commitment to innovation, continuous improvement, and operational excellence. We believe in offering superior customer service, providing quality fabrication solutions and well-made products to help drive growth in your business. Contact us to learn more about the Phoenix Metal difference and our advanced laser cutting capabilities, or request a quote today.

Do you have any questions or comments?