Phoenix Metal stands out for its expert craftsmanship, attentive service, and proven ability to support both custom and large-scale metal parts production. We offer comprehensive manufacturing services, from fabrication through final assembly, backed by rigorous quality standards and ISO 9001:2015 certification.

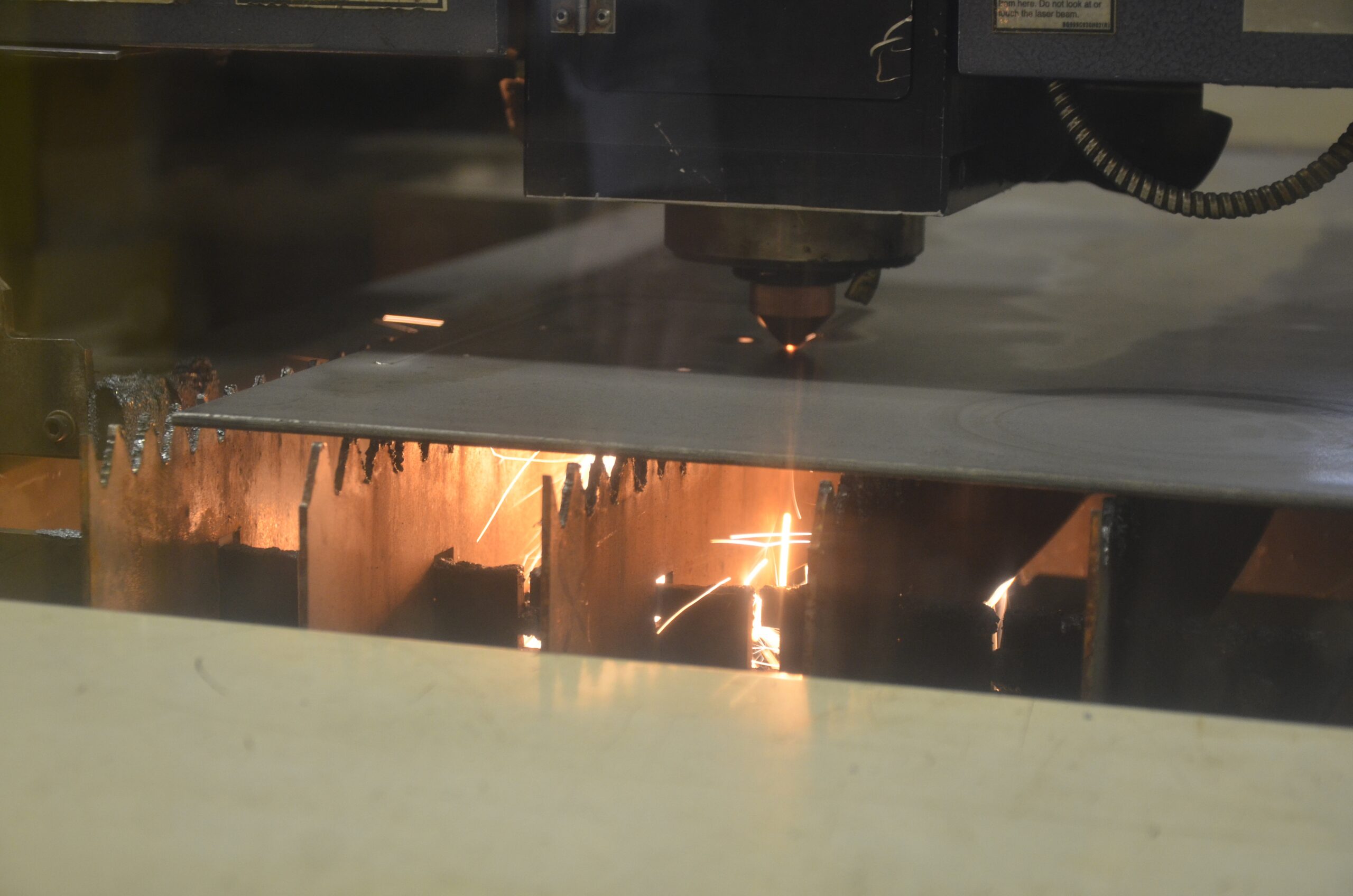

Laser Cutting

We invest in high-performance laser cutting systems to deliver speed, accuracy, and flexibility across a range of materials and part geometries. Our lineup includes:

- 2010 Mitsubishi 3015 LV-Plus 11-45CR-R: 5×10 CO₂ laser cutter with 4500-watt power and LS1+N Diamond Soft Software

- 2018 Mitsubishi 3015 EXF: 5×10 fiber laser cutter with 4500-watt power and zoom head

- 2025 AMADA ENSIS 3015 AJe Series (Coming in 2026): 5×10 fiber laser cutter with 12 kW power and automated loading capabilities

We routinely laser cut stainless steel, mild steel, and aluminum in the following thickness ranges:

- Stainless Steel: 0.020-0.500″

- Mild Steel: 0.020-0.500″

- Aluminum: 0.020-0.375″

Metal Fabrication

Phoenix Metal delivers precision metal fabrication services to clients across industries such as HVAC, material handling, audio, lighting, medical, power conversion, and office furniture. Our facility features a wide range of advanced equipment, including Strippit turret presses, a Mitsubishi laser, Cincinnati press brakes, and Lincoln welding systems to support a full range of fabrication processes:

- Punching

- Cutting

- Forming

- Welding

We typically work with steel, stainless steel, galvanized steel and aluminum in thicknesses from 24G (0.028″ nominal) to 1/4″ (.250″). In addition to our core fabrication capabilities, we offer several value-added and secondary operations, such as PEM insertion, graining, tapping, edge conditioning, deburring, and powder coating.

Our metal fabrication services allow us to produce a range of parts and components, including:

- Brackets

- Stainless steel and steel cabinets

- Enclosures, panels, and housings

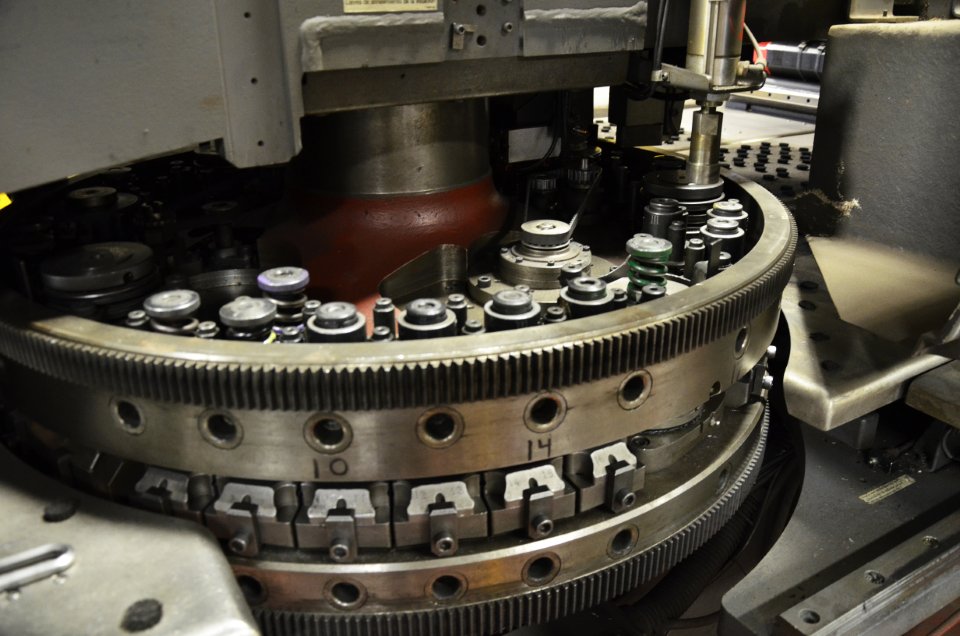

Metal Stamping

Our metal stamping services are powered by presses from trusted names like Bliss, Minster, Niagara, Verson, and Warco. With press capacities ranging from 15 to 200 tons, we accommodate material thicknesses between 0.007″ and 0.250″.

We work with a variety of materials:

- Hot Rolled Steel

- Cold Rolled Steel

- Stainless Steel

- Galvanized Steel

- Aluminum

- Copper

- Phosphorous Bronze

Many presses feature coil-handling equipment, such as uncoilers, feeders, and straighteners, allowing us to take on a broader range of stamped components for different industries.

Powder Coating

Phoenix Metal was an early adopter of automated powder coating and continues to expand this capability with updated systems and equipment. Our 450′ conveyorized powder line supports both manual and automatic application using epoxy, polyester, urethane, and hybrid formulations.

Our powder coating finishes include:

- Flat

- Semi-gloss

- Gloss

- Metallic

- Veins

- Hammer tone

Recent upgrades, including new Gema guns, a bake-off oven, and advanced wash systems, help us meet high standards for both aesthetic and functional finishes.

Welding

We employ AWS-certified welders skilled in various techniques to meet demanding project specifications. Our welding capabilities include:

- Spot welding

- Stick welding

- TIG

- MIG

We work with steel, stainless steel, and aluminum materials, and offer secondary grinding and stainless steel graining for a clean, finished result.

Assembly

Our assembly plant supports light mechanical and electrical assembly with manufacturing cells and multiple conveyor lines. We accommodate a wide variety of component types and frequently incorporate customer-furnished parts into final builds. This collaborative approach ensures product integrity while meeting customer timelines and performance expectations.

Subcontracting

Phoenix Metal enhances its in-house capabilities with a range of subcontract processes. These include:

- Anodizing (various colors)

- Black oxide

- Gold alodine

- Heat treatment

- Machining

- Screen printing

- Zinc plating

Our reliable subcontracting services help customers streamline production and consolidate sourcing without compromising quality.

Contact Phoenix Metal

From advanced laser cutting and metal fabrication to expert welding, assembly, and powder coating, Phoenix Metal delivers end-to-end manufacturing solutions under one roof. Our ISO 9001:2015-certified business management system reflects our dedication to consistent quality and continuous improvement.

Contact us today to explore how our services can support your next project.